Can I Use Eg Nails On Untreated Cedar Shake Roof

1. General Product Information

1.1 Product Type

1.2 Roofing Categories

1.3 Product Manufacturers

1.4 Manufacturing Process

1.5 Manufacture-Specific Standards, Codes Requirements, and Compliance

1.1 Product Type

one.1.1 Milk shake and Shingle Descriptions

The post-obit definitions are simply intended to provide a brief overview of the differences between basic product types. For more information on installation, production spacing, fasteners, and grading, please contact the Cedar Milkshake & Shingle Agency (CSSB). For full information, please view the product itemize at www.cedarbureau.org/pdf2013/Specsheet-low-res-03-27-xiii.pdf.

Certi-Dissever® Handsplit and Resawn Shake:

- Split up face up exposed with a naturally rustic appearance, sawn on dorsum

- Most mutual are 18 inch and 24 inch lengths

- Butt thickness ranges from iii/8 inch to one inch plus (Note: Jumbo resawn shakes take a minimum butt thickness of 1 inch)

Certigrade® Shingle:

- Sawn on both sides for a tailored advent

- Available in 16 inch (Fivex), 18 inch (Perfection) or 24 inch (Royal) lengths

- Barrel thickness is gauged using a stack of shingles to meet the proper measurement

Certi-Sawn® Tapersawn Milkshake:

- Sawn on both sides for a semi-textured expect with a stronger (pronounced) shadowline than a shingle

- Most common are 18 inch and 24 inch lengths

- Barrel thickness ranges from five/eight inch to 1½ inches

www.cedarbureau.org/cms-assets/documents/26244-377055.divergence-between.pdf

Effigy CEDAR-1-ane. Cedar Shake & Shingle Agency product Types and Grades.

Figure CEDAR-1-i describes differences in product quality using a grading system developed by CSSB and used to certify products produced by their members.

ane.1.1.ane Production Ingredients

Shakes and shingles are fabricated from either Western Red Cedar or Alaskan Xanthous Cedar. Much of the wood fiber utilized is from save forest, or wood that would otherwise be left on the forest flooring, thus making these products very environmentally friendly. Treated products use either a pressure-impregnated fire-retardant treatment or a preservative handling, but not both. A mail service-handling process helps fix the chemical in the forest.

1.ane.ane.2 Product Quality

The quality of the installed shakes or shingles will largely determine the longevity of a cedar roof. The highest quality shakes and shingles are 100% edge grain Western Red Cedar or Alaskan Yellowish Cedar and are gratis of knots and other growth defects and exercise not include sapwood. Lower-quality shakes and shingles volition include varying amounts of apartment grain, sapwood and knots.

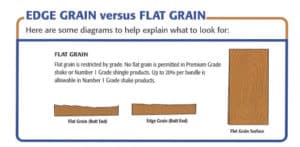

Effigy CEDAR-1-2. Flat Grain and Edge Grain Production Examples

Figure CEDAR-ane-2 illustrates the differences between flat grain and edge grain products. These differences can be easily identified by looking at the exposed surfaces and butts of shakes and shingles. No flat grain is immune in Premium Class cedar shakes or Number i Form cedar shingles. Premium Form shakes are the acme shake class, whereas Number 1 Grade shingles are the top shingle class.

Number i Form shakes are allowed to have up to twenty% apartment grain per bundle. Knots, apartment grain, sapwood and other defects in the exposed portion of the shake or shingle are a articulate indication of lower quality.

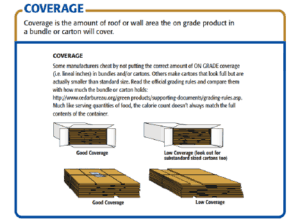

Coverage refers to the amount of on form lineal inches in a bundle of roofing textile (or a carton of sidewall material). Lower quality or "off-grade" products will not provide sufficient coverage without increasing gild quantity. An example demonstrating "coverage" is shown in Figure CEDAR-1-3.

Figure CEDAR-ane-three. Examples of practiced- and low-coverage quantities.

Traceability is adamant by the product label affixed to each packet of shakes or shingles. This is where one finds the manufacturer and inspection agency information. Information on how to read a Certi-label™ is provided at www.cedarbureau.org/manuals/imperial/2015/RFI/RoofManual-0407-i-p25.pdf.

1.1.2 Packaging

![]()

Figure CEDAR-1-4. Example labels for CSSB fellow member products which are treated.

Pressure-impregnated treated products, either fire-retardant treated or preservative treated, volition have a treatment label, such as one of those shown in Effigy CEDAR-1-4. If the production is already installed and the label is not bachelor, it will not be possible to determine whether the product has been treated without sampling and analyzing at an analytical laboratory. In these cases, it should be assumed that the product has not been treated.

1.ii Roofing Categories

The minimum roof slope on which Certi-label™ shakes are recommended is 4:12, and for Certi-label™ shingles, three:12. It is typical to meet installations with slopes greater than these. (IRC and IBC codes allow a minimum roof gradient of 3:12 for shakes and shingles.)

Mansard roofs installation guidelines are plant here:

http://www.cedarbureau.org/manuals/imperial/2016/RMI/CSSB-roof-manual-017-March2-p6.pdf

Low-gradient roof installation guidelines are constitute here:

http://world wide web.cedarbureau.org/manuals/imperial/2016/RMI/CSSB-roof-manual-017-March2-p7.pdf

1.3 Product Manufacturers

Boosted information nigh cedar shakes and shingles as well as links to manufacturers are available from CSSB at www.cedarbureau.org or past emailing info@cedarbureau.com.

1.iv Manufacturing Procedure

Cedar shakes and shingles take been manufactured for over 100 years, and not much has changed in the manufacturing procedure during this time, which is one of the fascinating things about this natural roofing product. The start stride in creating cedar shakes or shingles is to convert logs into round blocks. Bark, knots, and checks are removed from the blocks by cutting and/or sorting.

1.4.1 Cedar Shakes

When using logs, a boom of logs is towed to the river's edge. Each log is guided into the mill and a saw cuts the logs into advisable lengths called "rounds." Each circular is cut into wedges following the grain of the natural fiber. Material tin can also be cut into circular blocks in the forest harvest surface area.

The wedges or blocks are then made into "blanks" of the proper cut area and width to feed into the automatic milkshake machine. The blanks are guided through the bandsaw of the automatic shake auto past metallic fingers and rubberized rollers, and are sawn into two handsplit and resawn shakes. The two shakes tumble into the chute below to exist graded and arranged for shipment.

1.4.2 Cedar Shingles

Blocks motility up a conveyor and are placed on a table for the sawyer. A "shingle weaver" is an employee who operates two saws, one to cut shingles and one called a jointer saw stationed in from of the sawyer used to trim the edges of the shingles. Afterward being formed, the shingles are packed by stacking in bundles, which are compressed so the bandstick and metal strap can be securely nailed.

1.4.3 Weathering of New Product When Used as a Replacement Material

Replacement sections and individual shakes or shingles volition weather condition naturally to the same general grayness color as the rest of the roof within six to 9 months, on average. An case of this is provided in Figures CEDAR-i-five and CEDAR-1-six, which show the same roof in its unweathered (Figure CEDAR-1-5) and weathered (Figure CEDAR-1-6) land almost 9 months later. The weathering process is affected by the time of twelvemonth the replacement occurs and the surrounding environs, thus an exact timeframe cannot be provided.

Figure CEDAR-1-5. An unweathered cedar shingle roof.

Effigy CEDAR-1-6. The same shingle roof as shown in Figure CEDAR-1-v. A natural grey color was accomplished after about nine months of natural weathering.

i.five Industry-Specific Standards, Codes Requirements, and Compliance

ane.5.1 Bear upon Resistance—Hail

Impact resistance can exist evaluated using a standard test method outlined in UL 2218, as previously described in Chapter 3. Some CSSB member Certi-label™ shakes and shingles have withstood the impacts of up to 2-inch-bore steel balls dropped from a 20-human foot height, as per the UL 2218 test standard. Products having a Class iii or 4 designation are available, and Class 4 is the highest bear upon resistance rating. Contact the specific manufacturer for details on production offerings. The affect resistance ratings in the UL 2218 test standard are the same for all products, regardless of production type. Thus, a Form 4 roof covering is the aforementioned, whether discussing cedar, asphalt, metal, or whatever other roofing textile. For cedar roofs exhibiting hail damage, it is relatively elementary to supervene upon individual shakes or shingles. Considering of the previously mentioned color modify every bit a result of natural weathering, color matching is not necessary.

Caution: Not all cedar products are alike. Compliance with a exam standard such as UL 2218 volition exist labeled.

1.5.ii Wind Resistance—Shake or Shingle Uplift

The uplift resistance of cedar shakes and shingles from current of air is evaluated using UL 1897. In 2004, shakes and shingles provided by CSSB members were tested according to this standard test method (quaternary edition), with results of 90 psf (190 mph) for CSSB member shakes and shingles. Additional testing by Exterior Inquiry & Pattern, LLC showed results of 173 mph for CSSB shingles and 245 mph for CSSB shakes. A subsequent report past a Florida Registered Professional Engineer converted results, using no safety factors. Extrapolation calculations were performed for a specific business firm in the Miami-Dade County area of Florida using the analytical method for air current design of roof cladding ready forth in Section half-dozen of ASCE-vii-98 (American Society of Civil Engineers). For a full engineer'south written report, contact the CSSB.

CSSB member Certi-label™ products take met stringent Miami-Dade Canton, Florida requirements. Miami-Dade Canton, Florida, is considered to accept the toughest air current resistance regulations in all of Northward America and roofing products are evaluated using TAS 100-95 Uplift Testing. Water is also added into this test's wind stream to ensure the roof deck is free from leakage.

Caution: Not all cedar products are alike. Compliance with a test standard such as UL 1897 or TAS 100-95 will be labeled.

Annotation: The highest ratings for UL 1897 and TAS-100-95 standard examination methods for CSSB member products were both achieved when installations used band-shank nails.

For more information on cedar milkshake and shingle products and installation, meet the following resources (notation that the CSSB does not supersede edifice lawmaking):

http://world wide web.cedarbureau.org/manuals/imperial/2016/RMI/CSSB-roof-manual-017-March2.pdf

www.cedarbureau.org/cms-assets/documents/24826-485192.cssb-adjusters-guide-to-hail.pdf

or

www.cedarbureau.org/cms-avails/documents/23180-613565.weather-res-brochure.pdf

1.5.3 Fire

How long the roof over a building can ultimately resist the penetration of burn down is an important operation property. Fire ratings for roof coverings include Course A, Course B, Course C and "unrated" (i.eastward., coverings that don't meet Class C). These classes are the same for all covering materials, including asphalt limerick shingles, metal (aluminum and steel), and concrete tile.

The standard fire test, as specified by UL 790 (and ASTM E108, a similar test procedure) includes 4 parts, as indicated beneath, and a roof covering must come across the criteria established for each office in order to attain a given fire rating (i.e., Class A, B, or C).

- Intermittent Flame Test

- Spread of Flame Test

- Burning Brand Test

- Flying Brand Test

Course A fire-rated roof coverings or roof assemblies provide the highest level of burn resistance, followed by Form B and C. Untreated shakes and shingles are unrated, pregnant they practise not meet the requirements for Form C. Form A coverings are required on commercial and residential buildings in many wildfire-prone areas where building codes have been adopted. A Class A rating is accomplished through the use of a Class B burn down-rated shake or shingle with additional underlying materials that enhance the burn down-resistance of the roof assembly. Course B roofing systems are required for use on apartment buildings, condominiums and commercial buildings. If a cedar milk shake or shingle roof is immune in wildfire-prone areas, it will be required to exist Class A. Bank check with the jurisdiction having authority for details. Certi-label™ cedar milk shake and shingle roof coverings exist in all 3 classes, either by the shake or shingle itself, or through the apply of an assembly in the case of a Class A fire rating.

If you live in an expanse where the gamble of wildfire is high, CSSB member pressure-impregnated fire-retardant-treated cedar shakes and shingles provide an additional value-added component, proven in eight rigorous tests inside the UL 790 test standard:

- Intermittent Flame Test without amended rain test

- Spread of Flame Test without amended rain test

- Burning Brand Examination without amended pelting examination

- Flight Brand Examination without amended rain test

- Intermittent Flame Test later amended rain test

- Called-for Make Test after amended pelting test

- Flying Make Examination afterward amended rain test

- Natural Weathering Examination (tests 1 and 3–seven are redone afterwards natural weathering of 1, 2, 3, five, and x years exterior)

In lieu of an accelerated weathering procedure, California, in detail, requires burn-retardant-treated shakes and shingles to undergo natural weathering (i.due east., weathering outside). Fire tests are so conducted after the first, second, tertiary, fifth, and tenth year of weathering. The long-term weathering is intended to provide a better understanding of long-term operation over the anticipated service life of the milk shake or shingle when installed every bit a roof roofing.

Caution: Non all cedar products are alike. Compliance with a test standard such as UL 790 or ASTM E108 will be labeled.

1.half-dozen Unique Industry-Specific Flashing Details

Proper installation of flashing at roof valley and roof projections is critical. Installation details tin exist dissimilar for Certi-label™ shingles and shakes, then care must be taken to ensure proper installation. Flashing materials should be pre-painted on both sides using a skilful metallic or bituminous paint.

Recommended roof valley flashing material and installation are plant here:

www.cedarbureau.org/manuals/imperial/2015/RFI/RoofManual-0407-i-p10.pdf.

Recommended roof project flashing details are found here:

www.cedarbureau.org/manuals/regal/2015/RFI/RoofManual-0407-i-p11.pdf.

2. Installation Guidelines

2.1 Best Practices

2.ii Roof Sheathing Materials Options

2.iii Underlayment Options

2.4 Installation Methods

2.5 Accessory Items

2.1 Best Practices

Proper installations of cedar shakes and shingles have the post-obit characteristics that should exist visible without subversive evaluation (Run across Figure CEDAR-2-i):

- Uniform spacing between shakes of 3/eight inch to 5/8 inch, or uniform spacing betwixt shingles of 1/four inch to 3/8 inch

- Side by side course joints offset a minimum of 1½ inches (Note: Shingles allow no more than than 10% in direct alignment in alternating courses)

- No exposed fasteners

- No exposed interlaid felt (Notation: Shingles do not use a felt interlayment)

- Even courses

- No overexposed production (on a staggered butt application, no shake or shingle should be exposed across its maximum allowable exposure length)

- Acceptable cranium ventilation as required by code

Figure CEDAR-2-1. Examples of cardinal elements to be checked during visual inspection.

Spaced sheathing supporting shakes should be 1 inch x 4 inch or 1 inch x six inch dimension lumber. Spaced sheathing supporting shingles should be 1 inch x 4 inch dimension lumber. Plywood strips are never recommended, every bit they may not meet the ane inch x iv inch dimensional requirements, and may become weak and suspension betwixt trusses or rafters. The butt finish of shakes or shingles should projection 1½ inches across the fascia at the eave, and 1 inch beyond the rake border at gable ends. Shakes should have a starter course of i or two layers of cedar shingles or shakes (double or triple layer, as seen from the butt end) at the eaves and the first (eave) course for shingles must be a double or triple layer. Metal flashing should exist visible in valleys. The minimum extension requirement of flashing under the shakes or shingles should be noted (come across http://www.cedarbureau.org/manuals/imperial/2016/RMI/CSSB-roof-transmission-017-March2-p10.pdf and http://www.cedarbureau.org/manuals/royal/2016/RMI/CSSB-roof-manual-017-March2-p11.pdf) at transitions in roof slope, at ridges and forth intersections of the roof surface with any wall surface. Airtight valleys (where metallic is non visible) may exist immune past local edifice code, but are non recommended.

2.ii Roof Sheathing Materials Options

Shakes and shingles may be applied over spaced capsule. Solid sheathing is recommended for shakes and may exist required in seismic regions or under treated shakes and shingles. Solid capsule is also used in areas with air current-driven snow. The merely solid sheet sheathing that has been tested with Certi-characterization™ shakes and shingles is plywood, just manufacturers may allow application over OSB. Refer to your local building code or building official for requirements for capsule thickness/dimensions/grade. Boosted details and diagrams are available at www.cedarbureau.org/manuals/imperial/2015/RFI/RoofManual-0407-i-p3.pdf.

2.3 Underlayment Options

The recommended permeable interlayment for use with cedar shakes and permeable underlayment for shingles is No. 30 ASTM D4869 Type Four or No. 30 ASTM D226 Type 2. Information technology is never recommended to interlay felt with shingles, and would exist a violation of IRC and IBC lawmaking. (http://www.cedarbureau.org/manuals/royal/2016/RMI/CSSB-roof-manual-017-March2-p4.pdf)

It is recommended that milk shake installations include interlaying of felt between shakes starting ii times the exposed length of the milk shake above the shake butt.

Do non cover the entire roof deck with non-permeable underlayment. Check local building lawmaking requirements for proper attachment of underlayment, especially in high-wind zones.

2.iv Installation Methods

2.4.ane Exposure Length

The length of the exposed portion of a cedar milkshake or shingle depends on the length and quality of the shake or shingle. Tables CEDAR-ii-1 and CEDAR-two-ii provide general industry guidance on maximum exposure lengths for cedar shingles and shakes, respectively.

Tabular array CEDAR-ii-1. Maximum Recommended Exposure Lengths for Cedar Roof Shingles

| Maximum Recommended Exposure Length (inches) | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Gradient/Length | Number one Bluish Label | Number two Red Label | Number 3 Blackness label | ||||||

| Shingle Length | 16 | 18 | 24 | 16 | xviii | 24 | 16 | eighteen | 24 |

| 3:12 to 4:12 Gradient | 3¾ | iv¼ | 5¾ | 3½ | 4 | 5½ | 3 | 3½ | five |

| 4:12 Gradient and Steeper | 5 | 5½ | vii½ | 4 | four½ | 6½ | iii½ | 4 | five½ |

Table CEDAR-2-two. Maximum Recommended Exposure Lengths for Cedar Roof Shakes

| Slope/Length | Maximum Recommended Exposure Length (inches) | |

|---|---|---|

| Milkshake Length | 18 | 24 |

| four:12 Slope and Steeper | 7½ | 10 (a) |

| 24 inches 10 three/8 inch handsplit shakes limited to 7½ inch maximum atmospheric condition exposure per UBC and IBC | ||

2.four.2 Fasteners

Apply ii fasteners per milkshake or shingle every bit follows:

Stainless steel Type 316 fasteners are required for cedar shakes or shingles installed within 15 miles of salt water. In areas exterior the salt water zone, Type 304 stainless steel, Blazon 316 stainless steel or hot-dipped galvanized (with a coating weight of ASTM A153 Form D – 1.0 oz/ft2) fasteners are allowed (see http://world wide web.cedarbureau.org/manuals/imperial/2016/RMI/CSSB-roof-manual-017-March2-p12.pdf).

Stainless steel Type 316 fasteners are required for pressure level-impregnated treated cedar shakes or shingles in all areas.

Reducing product exposure does not reduce the number of fasteners needed.

There are industry recommendations for size (i.e., gauge) and length of fasteners to exist used depending on length and type of shingle or shake product being installed. Table CEDAR-two-three provides industry guidance on fastener blazon (size) and length, depending on the type of shake or shingle being installed.

Tabular array CEDAR-2-iii. Industry Recommended Minimum Fasteners

| Blazon of Milkshake or Shingle | Length of Milk shake or Shingle (inches) | Nail Type | Minimum Nail Length (inches) |

|---|---|---|---|

| Directly-Split Shakes | xviii | 5d Box | one¾ |

| Handsplit and Resawn Shakes | 18 and 24 | 6d Box | 2 |

| Tapersplit Shakes | 24 | 5d Box | 1¾ |

| Tapersawn Shakes | 18 and 24 | 6d Box | 2 |

| Shingles | 16 and xviii | 3d Box | 1¼ |

| Shingles | 24 | 4d Box | 1½ |

Non-galvanized and electro-galvanized fasteners should never be used with cedar shakes or shingles. If wrong fasteners are used, loose shakes or shingles, uneven courses where shakes or shingles take slipped out of identify, or fifty-fifty covering product that has slid into the gutter or completely fallen off the roof may occur. Wrong fastener placement can result in excessive cupping, crimper, or lifting of the cedar milkshake or shingle. These types of deformations tin can cause the roof to leak. You should non be able to pull a correctly installed shake or shingle out from its course without using proper tools.

UL 1897 loftier-wind ratings for cedar shakes and shingles were accomplished using ring shank nails and 1 inch ten 4 inch woods battens. Similarly, Florida Building Lawmaking TAS 100-95 loftier-air current ratings including Miami-Dade County approvals were achieved using ring shank nails and solid plywood decking. Consequently, the utilize of smoothen shank nails will lead to lower blast withdrawal capacities for the same size shank diameter, and rink shank nails would exist all-time used in high-wind zones.

For additional installation guidance including illustrations of different installation and capsule examples, meet www.cedarbureau.org/installation-and-maintenance/roof-manual.

2.5 Accessory Items

Access www.cedarbureau.org/installation-and-maintenance for details regarding accessory products, ventilation, ridge, fasteners, ventilation, valleys, installation and more.

3. Repair and Maintenance Guidelines

3.1 Natural Crumbling Vs. Damage

3.two Private Milk shake or Shingle Repair or Replacement

three.3 Blending New and Quondam

iii.iv Disposal/Recyclability of Products

3.v Fastener Failure

3.6 Maintenance/Budget Guidelines

3.7 Expected Product Life Cycle

3.ane Natural Crumbling Vs. Harm

The useful service life of a cedar milkshake or shingle roof will vary depending on many factors, including: local environmental conditions where it is installed, forest quality, quality of installation, care and maintenance performed, foot traffic, and amount of overhanging copse. See details regarding treatments, care, and maintenance at www.fpl.fs.fed.us/documnts/fplgtr/fpl_gtr201.pdf.

Proper age assessment takes into consideration whatever of the post-obit items: surface growth of mold, algae, or moss; leafage/pine needle buildup; moisture content; and surface butt/erosion. Some eventual curling, cupping and splitting on a cedar roof is normal, since cedar is a naturally durable textile. Due to 100% vertical grain content, Premium Form shakes and Number One Grade shingles do not have as much dimensional change as lower grades that allow some flat grain (see Effigy CEDAR-one-1 for description of grain structure). Excessive cupping and curling is ordinarily due to improperly placed nails, due east.thousand., too far away from the barrel cease or too far from the edge; improper installation of the ventilation arrangement between the sheathing system and the shakes and/or shingles; non-permeable underlayment installed over unabridged sheathing system utilizing an inadequate ventilation system between the not-permeable underlayment and the shakes and/or shingles; or due to lower-grade product. If information technology is determined that the excessive cupping and/or crimper will impact the integrity of the roofing organization, repair or replacement is necessary. Section ii.2 (Installation Guidelines) provides illustrations and steps that are typically taken in the repair of a cedar roof.

Changes in color occur over fourth dimension, changing from Western Ruby Cedar's natural ruddy brownish or Alaskan Yellow Cedar'southward yellow coloring to a silver or nighttime grey.

three.2 Individual Shake or Shingle Repair or Replacement

Effigy 3-1. Tools typically used to replace a cedar shake or shingle.

Cedar shake or shingle roofs can be repaired and the newly installed product will conditions to the same color as surrounding materials within six to nine months (on average). Tempest damage does non e'er mean a full roof replacement is necessary. In the aftermath of a storm, a miracle known as "neighboritis" (i.e., "My neighbor got a new roof, therefore I should get a new roof too.") may lead to more roof replacements than are really needed, which results in increased costs, increased wait times for repairs, and increased materials being disposed of in landfills. Sometimes information technology is better to repair a roof rather than completely supercede information technology, especially when considering a cedar roof department repair will alloy in with the original roof in a relatively brusque time catamenia. (Notation: Appropriate analysis and information can exist institute at www.cedarbureau.org/cms-assets/documents/24826-485192.cssb-adjusters-guide-to-hail.pdf.) Figure 3.two-ane shows tools typically used in the repair and replacement of cedar shakes and shingles.

Figure 3-2. Steps involved in one typical method for cedar shake or shingle replacement.

Effigy three-two illustrates steps involved in 1 method for shake or shingle replacement. Shims can be used to repair an occasional separate or defect from below, as shown in Figure 3-3. This is usually washed when the split or defect is less than i½ inches from the edge of the shingle below. The CSSB recommends that no more than xx% of a roof surface area be shimmed.

Figure iii-iii. Illustration of shim installation to repair a split or defect.

Boosted guidance on repairs and replacement of shakes or shingles is available at www.cedarbureau.org/cms-assets/documents/45094-350971.cmbrochure2011.pdf or www.cedarbureau.org/cms-avails/documents/24826-485192.cssb-adjusters-guide-to-hail.pdf.

iii.three Blending New and Old

Because new cedar shakes and shingles will chop-chop conditions to the same general grey color equally the rest of the existing roof, equally long equally the aforementioned blazon of product is being used, the new and old pieces will blend together after about six to nine months, on average.

3.four Disposal/Recyclability of Products

The cedar shake and shingle manufacture maximizes wood resources brought into manufacturing past using some salvaged woods fiber, or woods left over from past logging work or windblown material left on the forest floor. These materials are unsuitable for lumber mills, but can be used by cedar shake and shingle producers. Trees are a renewable resource so the use of wood edifice products is an environmentally sound choice. Wood is eminently recyclable and biodegradable.

3.five Fastener Failure

A Licensed Covering Consultant, or someone properly trained, should evaluate the issue to confirm widespread fastener failure. Fastener failure cannot be repaired; a tear-off and replacement of the shakes or shingles would, most likely, be the recommendation of the licensed independent assessor.

three.6 Maintenance/Budget Guidelines

CSSB offers data on the proper care and upkeep requirements for cedar roofs in its "Cedar Roof Care & Maintenance" guide available at www.cedarbureau.org/cms-avails/documents/45094-350971.cmbrochure2011.pdf. The reader of this document is urged to review this guide.

The USDA Wood Products Laboratory has a comprehensive publication (FPL-GTR-201) on wood roof maintenance at www.fpl.fs.fed.us/documnts/fplgtr/fpl_gtr201.pdf.

Some full general guidelines include:

- Trimming overhanging branches

- Regularly cleaning downspouts and gutters

- Removing leaves, branches, or other debris from the roof surface promptly

- Ensuring ventilation is bachelor year-round by keeping louvers and vents clear of droppings

3.6.1 Powerwashing

Figure three-4. Powerwashing damage.

High-pressure level-washing past inexperienced people will cause significant damage to whatsoever material, such as that shown in Effigy 3-4. Some debris tin easily be removed with garden hose force per unit area. If powerwashing is used, the roof should receive a topical treatment to restore the roof. The Cedar Milkshake & Shingle Bureau recommends having a professional assess each job on an individual footing. More information tin can exist found at www.cedarbureau.org/cms-assets/documents/45094-350971.cmbrochure2011.pdf.

three.6.2 Walking on Production

Figure 3-5. Footfall dissever harm (annotation no denting and new cedar color). Photo courtesy of Haag Engineering.

The less foot traffic on a cedar shake or shingle roof, the better, every bit foot traffic can cause damage such every bit that illustrated in Figure three-5. Unless admittedly necessary for assessment or repair, walking on these roofs should be avoided.

3.vii Expected Product Life Cycle

The life expectancy of cedar shake or shingle roofs will vary depending on many factors, including: local surroundings where installed, wood quality, quality of installation, intendance and maintenance performed, human foot traffic, and amount of overhanging trees. Proper age assessment takes into consideration any of the following items: surface growth/leaf/pine needle buildup, moisture content and surface butt/erosion.

4. Damage Bug

4.1 General Data

4.two Identifying Damage

iv.three Determining Hail Harm

4.four Determining Air current Harm

4.5 Determining Burn down Damage

four.6 Determining Cold Weather Damage

4.1 Full general Information

4.one.1 Product Identification

The characterization under the bundle strap of cedar roofing materials should include a "Certi-characterization™" designation at the top. Options include "Certi-Split®," "Certi-Sawn®" and "Certigrade®." Ridge cloth is chosen "Certi-Ridge®." An boosted label indicating "Certi-Concluding®" preservative-treated cloth or "Certi-Guard®" fire-retardant-treated material may also be found on the bundle or pallet if those respective treatments accept been impregnated into the shake or shingle. Other "Certi-label™" products be for sidewall applications. A useful diagram detailing the different components of a shake or shingle label, including manufacturer, product blazon, production dimensions and applicable codes/standards that the product meets are provided at http://www.cedarbureau.org/manuals/imperial/2016/RMI/CSSB-roof-manual-017-March2-p25.pdf.

To acquire about the differences betwixt a milk shake and a shingle, refer to Figure CEDAR-1-1.

four.i.ii Production Pick

Although good quality cedar shakes and shingles are readily available, in that location are suspect products in the market place. The Cedar Shake & Shingle Bureau provides an overview of how to choose the correct, quality-manufactured cedar roofing production at www.cedarbureau.org/cms-assets/documents/67060-723658.qcbrochure.pdf. Non all cedar shake and shingle products are the same.

All Cedar Shake & Shingle Bureau members are listed on the CSSB website: www.cedarbureau.org (look for the "Find a Member in Your Area" box at the lesser eye of the page). Affiliate members include contractors, distributors, retailers, wholesalers and brokers. Homeowners and Claim Adjusters typically deal with contractors who will and then purchase products from a member supplier. You can also contact member manufacturers straight (run into http://www.cedarbureau.org/find-a-member/manufacturers/) if you have questions nigh their specific product and/or limited warranty.

For product pick, refer to the product catalog at world wide web.cedarbureau.org/pdf2013/Specsheet-depression-res-03-27-13.pdf.

4.2 Identifying Damage

Thorough cedar roof inspections must be performed on the roof—these inspections cannot be conducted from the ground. All areas of the roof should exist checked for possible damage, including fasteners and flashings. All of these elements work together to form the cedar roofing system. Notation that normal wear and tear every bit a effect of weathering will occur over fourth dimension. Normal weathering does not include storm damage, and may consist of splitting, cupping and curling. Excessive amounts of these items could hateful that a lower-quality textile was used or that the cloth was improperly installed. Improper installation tin include poor fastener placement. Pay item attention to missing or dislodged fasteners, and underlayment exposed to the atmospheric condition. Missing or dislodged fasteners can result in loose shakes or shingles. Excessive damage of any kind indicates that activeness is necessary.

The CSSB does not recommend new installations or retrofitting where a non-permeable membrane covers the entire roofing deck. Installation of shingles and shakes directly to roof decks covered with a non-permeable underlayment can lead to overheating of the forest and the resulting excessive drying-related defects such as keen and splitting. Use of a not-permeable membrane can also issue in the accumulation of moisture on the underside of the shake or shingle. Over time the resulting moisture buildup can result in fungal degradation of the roof covering. If you find a damaged roof that was constructed using a non-permeable underlayment, a more detailed assessment and analysis of the roof should be conducted to determine the cause of the degradation.

When inspecting a roof, utilize a worksheet that lists items to be checked and evaluated. The worksheet should include: roof area; historic period of roof; type and thickness of decking; flashing type and the type of flashing installed in the valleys, roof gradient and whatever gradient changes, ridges and intersections with walls; installation and production quality; roof slope; size and type of shakes or shingles; and number and blazon of damage exhibited by the shakes or shingles. All of these factors are used to make repair versus supplant decisions. One should consider replacement of the damaged roof/roof segment when repair price eighty% of the replacement cost. Be sure to factor in relevant replacement product costs associated with hips and ridges, valleys, re-decking, tear-off, and other more complicated expanse works. Insurance industry claims software or the analysis procedure and Repair Costs Formula (www.cedarbureau.org/cms-assets/documents/24826-485192.cssb-adjusters-guide-to-hail.pdf) can be used to assist brand this determination.

four.3 Determining Hail Damage

Figure CEDAR-4-ane. Hail impact split. Photo courtesy of Haag Engineering science.

Cedar roofs can rebound from minor impacts from hail, leaving virtually no evidence of the storm subsequently normal weathering is immune to take its course. Furthermore, cedar roofs practice not always demand to be completely replaced after a hailstorm. Small hail impacts may bear witness up as light-colored spots on the weathered surface of the roof. Larger hail impacts can event in splitting of shakes or shingles, or larger fractures that clearly crave replacement. Figure CEDAR-four-1 illustrates a split caused by hail bear upon. Note the low-cal wood color on the inside of the split.

Effigy CEDAR-4-2. Weathering dissever and pocket-size hail affect marks. Photo courtesy of Haag Engineering.

Figure CEDAR-4-2 shows a weathering split and impact marks from minor hailstones. The gray color forth the within of the dissever indicates that information technology is an old divide. At that place is no indication of an impact mark (such equally the one shown in Figure CEDAR-4-1) that might take caused the split.

Figure CEDAR-4-iii. Many small hail bear on marks, but no splits in shingle. Photo courtesy of Haag Engineering.

Effigy CEDAR-4-iii shows many small-scale hail impact marks, just no dissever. This shingle or shake can be expected to weather to a consequent color within months and does non crave replacing.

Figure CEDAR-4-iv. Intentional damage from ballpeen hammer (annotation regular blueprint). Photo courtesy of Haag Engineering.

Types of damage, including intentional damage, fracture from someone walking on the shingles or shakes, and impairment from powerwashing, are shown in Effigy CEDAR-4-4, Figure CEDAR-four-5, and Figure CEDAR-4-six respectively.

Effigy CEDAR-4-5. Footfall dissever harm (note no denting and new cedar color). Photo courtesy of Haag Engineering.

Figure CEDAR-4-6. Powerwashing damage.

iv.four Determining Wind Damage

No specific marks or shape changes can be used to point wind damage to a cedar roof. If there is wind damage, it is most probable that fastener pull-through or dislodged fasteners would exist visible. These failures likely result from poor quality and/or wrong fasteners and fastener spacing, or over/nether-driven fasteners. These can issue in tearing around the fastener head, or roof areas lifting due to lack of fastener belongings strength. Loose shakes or shingles, uneven courses where shakes or shingles accept slipped out of place, or roofing product that has slid into the gutter or completely fallen off the roof, can exist an indication of fastener failure or incorrectly driven or positioned fasteners.

In extreme wind weather, harm from big windblown droppings, such as air workout units, is possible. Further investigation volition determine if repair or replacement is necessary.

4.5 Determining Burn Impairment

Visual clues could be: shakes or shingles charred by fire, damage to capsule from flame or venting performed by Burn Department when brining the burn down nether control. The post-obit link will provide additional data: www.fpl.fs.fed.the states/documnts/fplgtr/fplgtr190/chapter_18.pdf.

4.vi Determining Cold Weather condition Damage

four.6.1 Snow Retentivity

Determining how much snow is too much can only be determined by the pattern of the structure, the species of the shake or shingle, grade and dimension of roof rafter lumber. The Canadian Wood Council (www.cwc.ca) and the American Wood Council (world wide web.awc.org) take pattern/load values on their websites.

Leaving snow on a woods milk shake or shingle roof for a long menstruum of time will not be detrimental to the shake or shingle. There will be trivial to no change in the color of the forest milkshake or shingle.

Dimensional change concerns of radial and tangential grain are addressed in the keyway spacing mandated in the IRC and IBC Codes. With proper keyway spacing, there should be no dimensional change functioning issues (i.e., those related to swelling).

Sliding ice and snow are hazards that should be given chief consideration in the total building pattern. To minimize snowfall memory, a steeper gradient is better. Chimneys should exist located at the ridge or gable ends. To minimize corrosion issues, plumbing pipes should exist located on within walls, extending between raters and vented at the ridge. If this is non practical, and then plumbing vent pipes should exist galvanized iron, well anchored inside the roof. Wide overhangs at the eaves should be avoided as they provide big cold areas for snow and ice buildup. A strip of metal (i.east., drip border) along the eaves helps shed ice quickly.

More than pattern information for cedar roofs in cold regions is provided here:

www.cedarbureau.org/manuals/imperial/2015/RFI/RoofManual-0407-i-p17.pdf

www.cedarbureau.org/manuals/imperial/2015/RFI/RoofManual-0407-i-p18.pdf

4.half-dozen.ii Ventilation

Adequate ventilation helps to maintain a common cold roof during the winter which will help forbid ice dams and allow improved drying of sheathing if moisture does accumulate. Inadequate ventilation tin can contribute to mold buildup on roof sheathing within the attic or biodegradation of the sheathing and roof rafters or trusses.

A cold roof—or vented roof—is recommended. This system allows a abiding menstruation of cold air above the insulation but below the roof roofing. The venting space should be sufficient to let a free flow of air from eave to ridge.

Boosted design data can be constitute hither:

www.cedarbureau.org/manuals/royal/2015/RFI/RoofManual-0407-i-p17.pdf

www.cedarbureau.org/manuals/imperial/2015/RFI/RoofManual-0407-i-p18.pdf

Ventilation in the cranium expanse allows the bottom of the capsule to dry out in the event the capsule gets moisture due to condensation or a modest leak.

Ventilation likewise allows the attic expanse to accept lower temperatures during the fourth dimension of year when ambience outdoor temperatures are high.

four.six.3 Ice Damming

The following documents will provide information on the causes, and "do'due south and don'ts" for minimizing water ice damming on a roof.

bct.eco.umass.edu/publications/past-title/preventing-ice-dams

www.extension.umn.edu/environment/housing-technology/moisture-management/ice-dams

Source: https://ibhs.org/guidance/ricowi-roof-guide-cedar-shingles-and-shakes/

Posted by: stubbslerning.blogspot.com

0 Response to "Can I Use Eg Nails On Untreated Cedar Shake Roof"

Post a Comment